Beginning with early accounts of the prowess of the legendary Toyota Production System (TPS), this article offers personal reflections on the fabric of TPS and present day explanations of Lean.

In the late 1960s, Frank Pipp, an assembly plant manager for a Ford Motor Company factory, instructed his staff to purchase competitor’s cars. His plan was to have the final assembly team disassemble these cars and learn firsthand how they were assembled. At that time at Ford, if two connecting parts could be assembled without the use of a handy rubber mallet, then these parts were known as “snap fit.” In his account to Xerox, CEO David Kearns (Reference: Prophets in the Dark, by David Kearns), the remaining parts required mallets to assemble. To Pipp’s amazement, one car purchased was 100% snap fit. He did not believe the results and instructed the team to repeat the assembly operation. They did and found again that the Toyota pick up truck was 100% snap fit. The discovery was not lost on Pipp. In contrast, he noted that the “Dearborn people,” from Ford’s corporate offices, were invited to look over the truck themselves and witness the assembly team’s discovery. According to Pipp:

“Everyone was very quiet, until the division general manager cleared his throat and remarked, ‘The customer will never notice.’ And then everyone excitedly nodded assent and exclaimed, ‘Yeah, yeah, that’s right,’ and they all trotted off happy as clams.”

Pipp’s documentation of the striking difference in the assembly process within Toyota, by comparison to Ford, was to be found again in the early 1980s when teams from both Ford and General Motors began to routinely visit Toyota’s operations in Japan.

Larry Sullivan, from Ford, wrote an account of the visit he made to Japan in 1982 to “study quality systems at a variety of automotive suppliers.” (Reference – Reducing Variability: A New Approach to Quality, L.P. Sullivan, Quality Progress, July 1984). Included were these remarks:

“The most important thing we learned was that quality in those companies means something different from what it means in the U.S. – that it is in fact a totally different discipline. Over the years, Japanese managers, engineers, and workers have been very successful in reducing manufacturing costs by adopting more enlightened quality thinking and by applying more technical quality methods. In other words, quality in itself has not been the primary motivation in Japan; profit is the main objective and quality (methods) is merely a means to improve profit…Of foremost importance is the new definition of ‘manufacturing’ quality as minimum variation from target.“

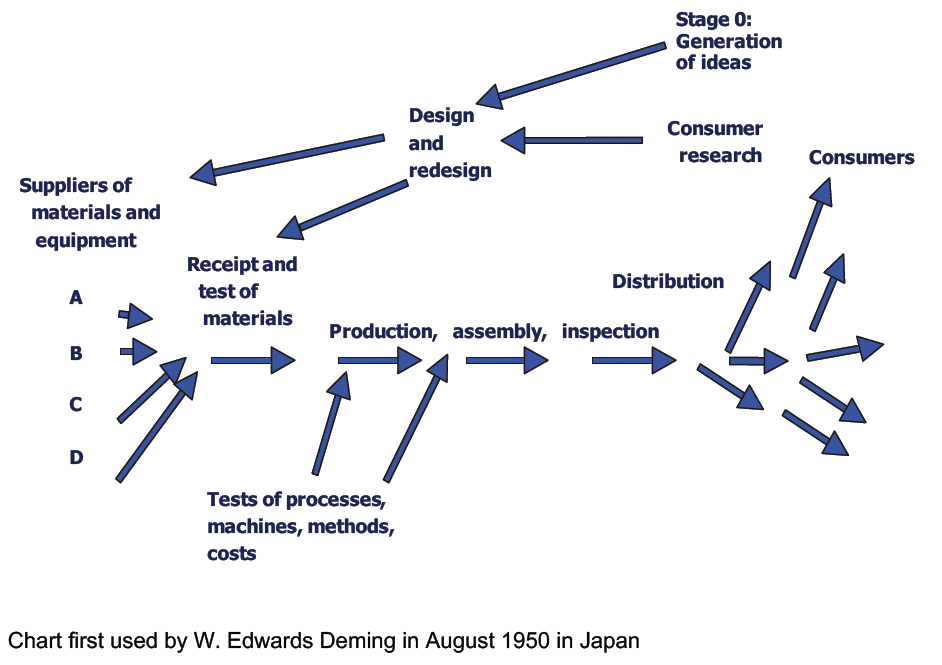

With the preceding account by Larry Sullivan as a second reference point, consider what happens when a craftsman works on the design of a product at home, where the customer and producer are often one in the same. One person designs the product, procures the raw material, fabricates the corresponding parts, and then assembles them into the final product for personal use. The producer-as-customer is quick to judge the product quality and adjust the design-procurement-fabrication-assembly process, as needed, should the resultant product quality fall short of expectations. This system of feedback is much the same was what was explained by W. Edwards Deming to several dozen executives in Japan in 1950. Specifically, he suggested to them that they view “production as a system” and left them with the now famous process diagram below.

Figure 1 – Production Viewed as a System

As shown in Figure 1, consumer research in this process is essential to providing feedback on the product design to address shortcomings, if not suggestions, for product improvement. Such a viewpoint of gathering consumer feedback is considered vital to organizations seeking to improve product quality. These efforts are often aligned through a non-linear process improvement cycle that resembles the hand drawn version of this figure, which Deming shared with Japanese executives long before the aforementioned discoveries by Frank Pipp and Larry Sullivan. Years later, in 2005, Dr. Shoichiro Toyoda, Chairman and former President (1982-1999) of Toyota, accepted the American Society for Quality’s Deming Medal. In doing so, he offered:

“Every day I think about what he meant to us. Deming is the core of our management.”

While the do-it-yourselfer in the garage is not necessarily a master craftsman, the connection to the model of a single person engaged in most of the design-procurement-fabrication-assembly tasks is relevant to the topic of quality and an appreciation of the Toyota Production System and how it differs from a mass production system. Likewise, the resulting product quality of a master craftsman is relevant and the association of Toyota’s products with leading levels of quality will be explained later in this article as the difference between “part” quality and “part of” quality.

Fast forward to the mid-to-late 1980s, when a research team at the Massachusetts Institute of Technology, led by Daniel Jones, Daniel Roos, and James Womack, surveyed production systems at 90 automobile assembly plants in 17 countries. Their conclusion was that the results from these plants could be very neatly affinitized into three subgroups that fell along geographic lines; Europe, the U.S., and Japan. Coinciding with these categories were the labels “craftsmanship” and “mass production” for Europe and the U.S., respectively. A new term, Lean, was needed to describe the artful blending of craftsmanship, and its attention to detail in relationships, with the speed and low cost of mass production.

Before the era of mass production was envisioned in the late 1700s, craftsmen were relied upon to deliver products of superb quality to those who could afford them. As an alternative to this high quality – high cost model, Honore Blanc, envisioned an alternate production model with drastically reduced costs. Blanc, who lived in France, is given credit for conceiving the production model of “interchangeable parts” as an alternative manufacturing method to craftsmanship; one which could deliver lower-cost products to the masses. At this time, Thomas Jefferson was the U.S. Ambassador to France. Jefferson later became the visionary champion for the adoption of interchangeable parts as a strategy for production within the U.S. After Blanc declined his offer to move to the U.S., the idea of interchangeable parts was shared with Eli Whitney. Long before Henry Ford’s moving assembly line, Whitney is given credit for leading the way for the implementing interchangeable parts within the U.S. (soon to be known as the American method of production), and his company was the first to be given a contract from the U.S. government, in 1798, for the design and manufacture of a product (a rifle) with interchangeable parts.

As a personal example of craftsmanship, let’s return again to the example of the do-it-yourselfer in the garage, this time doing home repair.

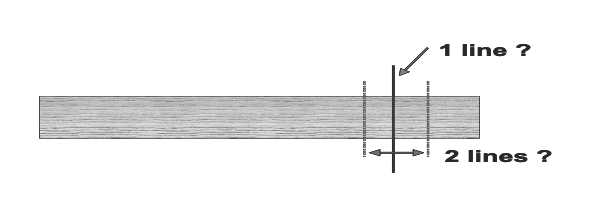

Imagine that a piece of wood molding is needed to replace a damaged length of wood in between two existing pieces. We begin with a piece of molding that is too long and needs to be cut to length. In rapid order, the required length is measured, and the piece is marked for cutting. As a next step, a saw is readied. Consider how many lines one typically would draw across the top face of the wood before making the cut. That is, instead of using short marks to indicate where to place the saw, how many lines would be drawn across the top face to guide the placement of the saw blade during the cut? Most often the solution is to use a single line and subsequently cut close to this line. Why is the habit not two lines, as in the standard industry use of manufacturing tolerances with an acceptable range, in keeping with the practice of interchangeable parts? The “single line” answer implies a belief that there is a “target” length for this piece of molding and indicates a strong intuitive sense of knowing that the piece of wood is “part of” something rather than merely a “part.” A “part of” perspective is likely when engaged in a home improvement project where connections are visible and immediate. In the molding example, the lesser quality of the fit if the piece is longer or shorter than desired will be obvious. Any effort required to adapt the molding piece, because of variation in its length – a little too long or too short – represents Quality Loss, a concept introduced and developed in Japan by Genichi Taguchi.

Figure 2 – Marking a piece of wood molding before cutting it to size

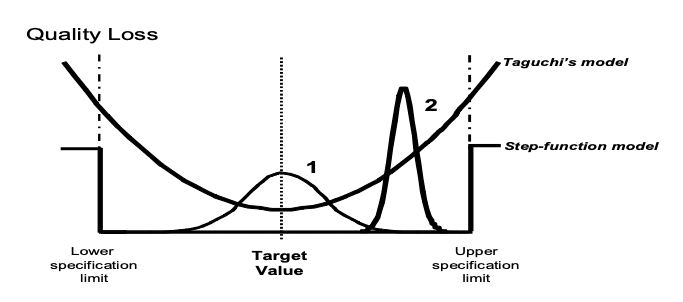

As shown in Figure 3, Taguchi’s Quality Loss Function model increases continuously as the piece of molding length misses the target by larger and larger amounts in both directions – shorter or longer than the desired target dimension. In either case, the extra effort (loss to the do-it-yourselfer) is both finite and real, just as the use of hammers to assemble parts at the Ford plant were finite and real to Frank Pipp and his assembly team. Could it be that such losses are accounted for and then reduced through routine efforts within the Toyota Production System to better align the organization’s resources? That is, the resources of time and effort would be invested to produce a given dimension closer to its target value, but only if this effort was less than the corresponding reduction in loss, thereby making the effort a worthwhile investment of resources. According to personal conversations with Genichi Taguchi, Toyota has been a world-wide leader in the use of his Quality Loss Function concept to direct efforts to move from the traditional “part” quality model to one in which a greater emphasis is placed on “relationship quality,” as in “how far from the target value is a given dimension?”

According to Genichi Taguchi, Toyota’s efforts with the Quality Loss Function date back to his consultation role in the early 1950s. Within 10 years, he was honored in Japan with a Deming Prize in Literature for his contributions to a new definition of quality. Specifically, as noted by Larry Sullivan, he defined quality as “the minimum of loss a product causes to society after being shipped.” By contrast to the mass production system’s “conformance to requirements” model of quality, which remains the standard of quality in systems such as “Zero Defects” and “Six Sigma Quality,” Taguchi suggested a model that looks at quality from the vantage point of the relationship of a producer to its customer. In doing so, Taguchi acknowledged the existence of a never-ending connection (and impact) between the provider of the “part” and what it is “part of.” The technical aspects of this holistic model are shown in Figure 3, where the horizontal axis represents the specific value of a part dimension on a continuum and the vertical axis represents the associated “Quality Loss” for a corresponding part dimension. If one considers the “Quality Loss” to be the “extra effort required” for installing a part of a given dimension, the distribution (“Quality Loss Function”) theorized by Taguchi – a simple parabola centered on the target dimension (with minimum loss at target), accounts for the loss associated with dimensions that are not produced to target dimensions.

Figure 3 – Genichi Taguchi’s Quality Loss Function reflects a continuous model of part quality. Histograms 1 and 2 are examples of possible results for 2 suppliers of parts.

Taguchi’s model brings in to question the mass production belief that all parts within the range of the tolerances are “equally good,” and, therefore, absolutely interchangeable. The degree to which variation from a target dimension produces harmful effects downstream in the “organization and society” is a function of the steepness of the Quality Loss Function, which in turn depends on the specifics, or context, of the system which the part is actually a “part of.” Of foremost importance, Taguchi’s model suggests that interchangeability be modeled as something that is relative and not absolute.

By comparison to Taguchi’s model of continuous Quality Loss, the mathematical model associated with the mass production concept of “Zero Defects” is a “step-function.” Figure 3 offers a side-by-side comparison of these models. In keeping with a step-function model, all parts within tolerance are “good and equally good.” No change in quality is perceived across this range and the only changes in quality that do occur happen instantaneously at the transition across either of the two manufacturing tolerance limits. Inspired by Taguchi, and influenced by Deming, Toyota has long modeled quality as a continuous feature, rather than discrete, with a preferred value (target) that provides for minimal loss. Such a view leads to the conclusion that any deviation from a target dimension results in some degree of loss being imparted downstream by the part after its shipment to the customer.

______

The content of this blog was prepared as an article for the first edition of the Lean Management Journal, later known as The LMJ. This article is the first of a series I am preparing in collaboration with Dick Steele, a Board Member of The Deming Institute, to offer our thoughts on the legendary Toyota Production System and its connection to the management system within Toyota, and how it was inspired by Dr. Deming.

As a student of Drs. Deming and Taguchi, I have a special fondness for the systems thinking of Russell Ackoff and the cosmic interpretation of the Toyota Production System provided by H. Thomas Johnson, for what their thinking contributes to my evolving theory of how Toyota operates. For this reason, I am constantly in search of explanations of Lean that reflect the fabric of Deming and Taguchi, along with the systemic insights of Ackoff and Johnson. Beginning with this edition of the Lean management Journal, I encourage our readers to think beyond the prevailing explanations of Lean and consider the possibility that the fabric of the Toyota Production System is more closely aligned with the usage of Taguchi’s Loss Function thinking than has ever been acknowledged in the Lean literature, which remains dominated by a part-like focus on efforts such as single-piece flow, standardization, zero defects, zero waste, and the elimination of non-value work. Such a focus will needlessly limit Lean to shop-floor applications associated with volume production and continue to view employees as Taylor-like interchangeable parts.

WANT MORE?

Follow The Deming Institute on LinkedIn to get updates on the most exciting and relevant events and news happening in the broader Deming community.