THE DEMING INSTITUTE BLOG

| Appreciation for a System, Continual Improvement, Theory of Knowledge

Extraordinary Results

This is the final installation of Martin Laurent's story of transforming a GM plant using the Deming philosophy. He shares the extraordinary results of his team's efforts.

| Appreciation for a System, respect for people

Our Unique System

Martin Laurent's story of transforming a GM plant using Deming continues. (Part 3 in a 4-Part Series)

| Continual Improvement, Deming's Ideas in Action, System of Profound Knowledge

Putting Deming Thinking into Practice

Marty Laurent describes how he took Deming thinking into a GM plant. He adapted to meet the local conditions and, over nine years, his team achieved tremendous success. (Part 2 in a 4-part series.)

| Deming Philosophy, System of Profound Knowledge | 2 Comments

15 Minutes That Lasted 6 Hours

Guest post by Marty Laurent: My 15-minute presentation lasted 6 hours. By the end, I had learned more from Dr. Deming than I had in all my years in college. (Part 1 in 4-part series.)

| Appreciation for a System, Education, Education | 2 Comments

Education at a Crossroads: The Perils of Competition in K-12 Education

The aim of this article is to specifically address the topic of competition among schools and districts as a means to improve the performance of the education system. (Hint: it doesn't work!)

| Deming Legacy, Dr. Deming | 3 Comments

A Toast to Dr. W. Edwards Deming in Honor of his Birthday

It is a great pleasure to offer a toast to Dr. Deming. He was a friend and mentor for 30 years. I cried when he died and would cry again today if I were here with you. And I am not alone. Dr. Deming touched many people’s lives in a very deep way.

| Psychology, Understanding Variation | 3 Comments

It’s More than Numbers: New Insights About Common and Special Cause Variation

In this guest post, Dr. Doug Stilwell shares his fresh insight into common and special cause variation - and how that concept can apply to emotions.

| Deming Legacy, Dr. Deming, Education | 5 Comments

The Joy and Irony of a Leadership Career

In this guest post, Dr. Doug Stilwell reflects on his long career in education and shares the impact of Dr. Deming’s teachings on his work.

| data, Understanding Variation | 1 Comment

A Beginner’s Guide to Control Charts

The Deming philosophy is like an onion: it’s got layers. I’ve been studying the System of Profound Knowledge and all it entails for almost 2 years, and I’m at layer 4 or 5, I think. I love the aspects I understand and how my thinking has changed. Plus, I’m constantly learning new things that shift […]

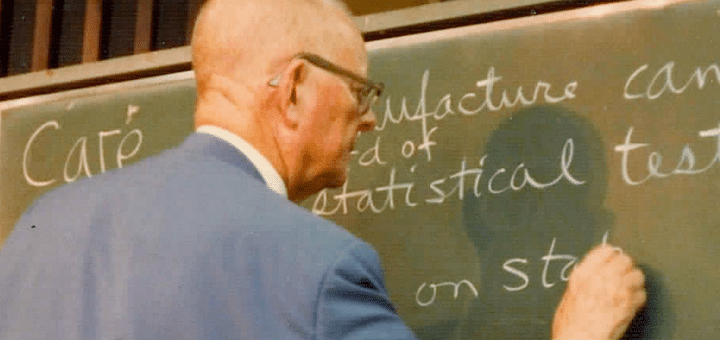

| data, Deming Legacy, Understanding Variation | 1 Comment

If Only I Knew Then What I Know Now

(Guest post from Edward Martin Baker) As we get older, more experienced, and maybe wiser, some of us may reflect on what we could have done differently when we were younger - if we knew then what we know now. I have recently been reflecting on my teaching of introductory statistics when I was a graduate school teaching fellow in the distant past.